|

The Facade is the buildings outermost surface. The direct bonding of ceramic tiles means that possible stresses are in the end transferred to tiles. Thus, facade design, the bonding system and the products used must provide the proper levels of safety by guaranteeing that these movements are properly absorbed.

Tile installation

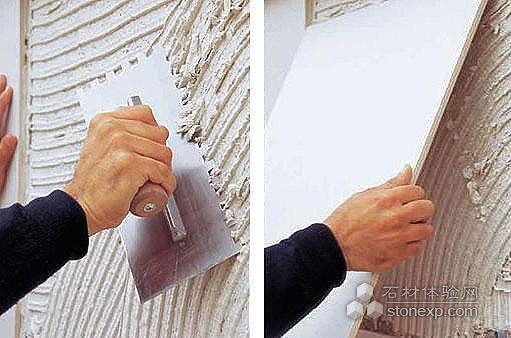

The floating and buttering method should always be used, which consists of spreading the adhesive over the substrate and combing it using a notched trowel. Trowel size should be suitable for the tile format being installed. Afterwards, a thin layer of adhesive is applied to the back of the tile with the flat side of the trowel, so as to ensure full coverage of the tile when it gets pressed down into the adhesive. The adhesive's wettability (coverage) should be checked on a regular basis and should be practically 100%. As an additional safety measure in the Bonded Façade system, metallic fasteners are used to attach each one of the pieces. These fasteners are screwed directly into the substrate and are completely hidden once the façade is grouted. Thus, this effectively makes up for any installation errors and provides the façade covering with total safety.

Installation joints

The fact that ceramic pieces remain highly rigid when movements and deformations occur makes it necessary to leave spaces between pieces so that they are better able to absorb these stresses. Therefore, from a technical standpoint it is necessary to render installation joints between tiles, leaving a minimum width of 5 mm (open joint). Tiles should never be installed end-on-end (butt-jointed). The product that should be used to grout these joints is colorstuk, from the professional line of cement-based coloured mortars for grouting installation joints (type CG2, as per EN 13888). The water in the mix should be totally replaced with cl-stuk, a synthetic resin-based latex. This additive helps to increase the imperviousness of joints, while enhancing the grout's flexibility and bonding strength.

Expansion joints

These joints are of fundamental importance in conserving the ceramic-tiled covering against the building's own structural movements as well as those brought on by external factors which may affect the façade. They help to reduce the stresses that may be transmitted to tiles and cause breakage or detachments. These joints should be rendered in those areas where the nature of the substrate changes, as in the case of windows, corners and shifts in plane along the façade. They should also be used in the presence of other structural elements, as with the union between floor slabs or fixed elements. Expansion joints should form sections no larger than 12-16 m2, with these being as square as possible; recommended joint width is 8-10 mm. To seal these joints, use s-502 acetic silicone-based sealant, which offers a high degree of elasticity and weather resistance. |